Specializing in R&D, smelting, sales, and service of special metal alloys

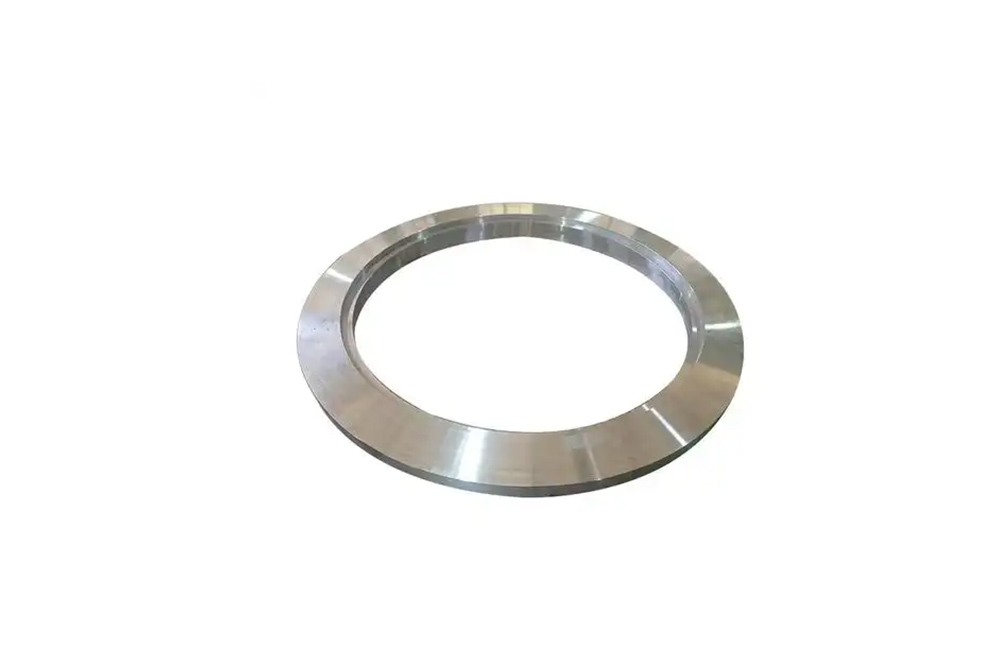

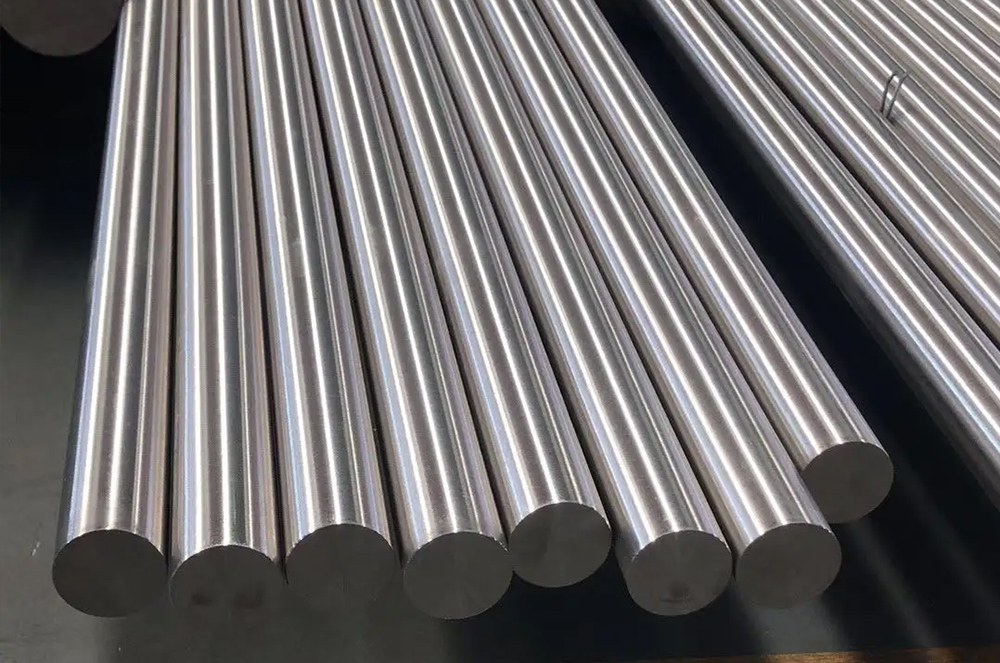

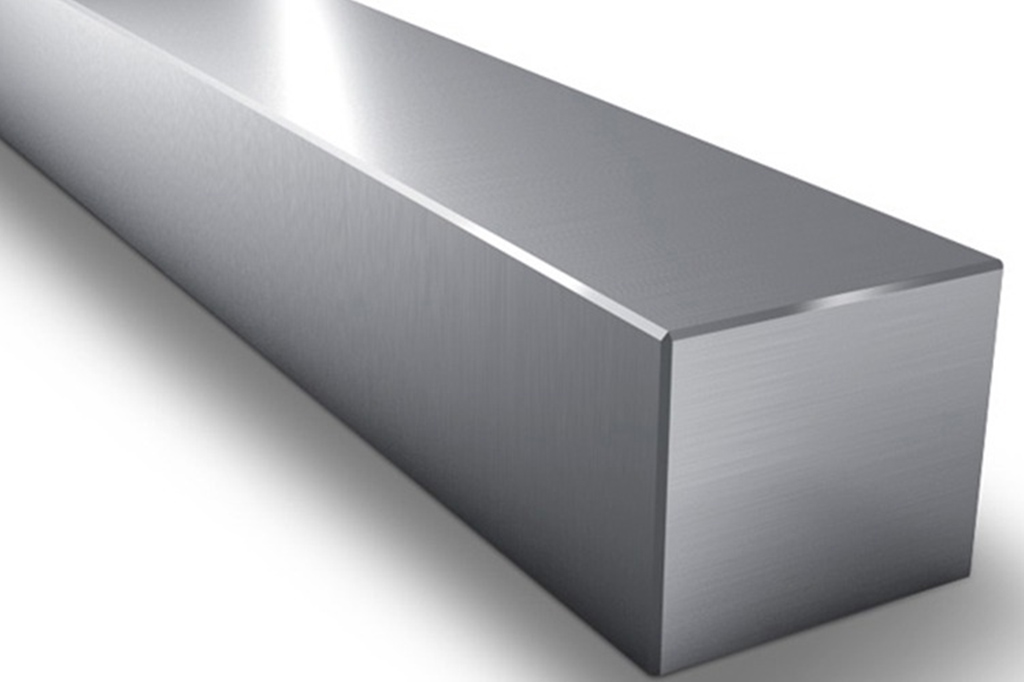

Customizable products include steel ingots, electroslag ingots, consumable ingots, billets, bars, special steel plates, and high-temperature alloy sheets.

About US

Wuxi Marley Metal Technology Co., Ltd.

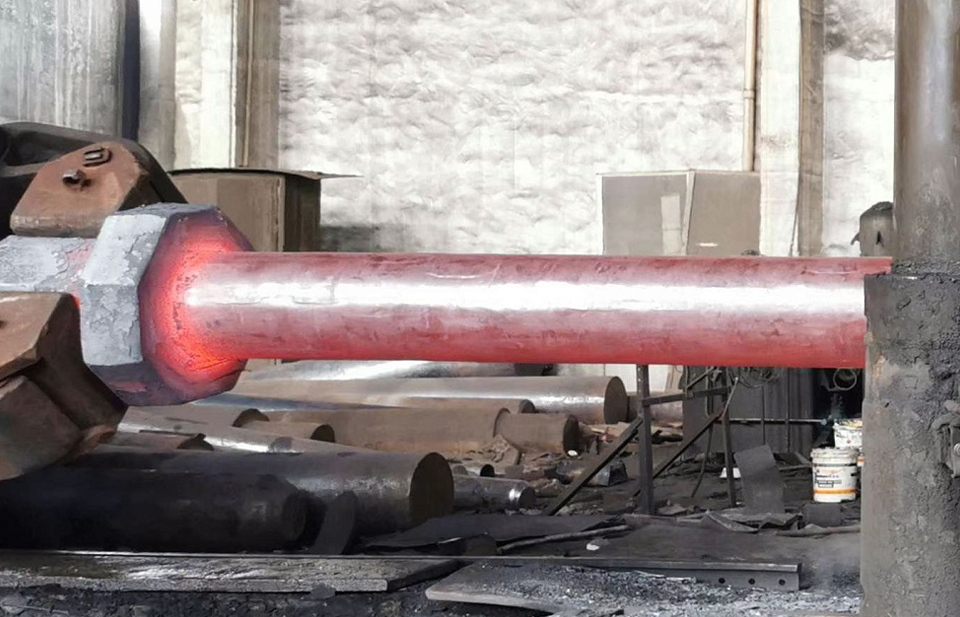

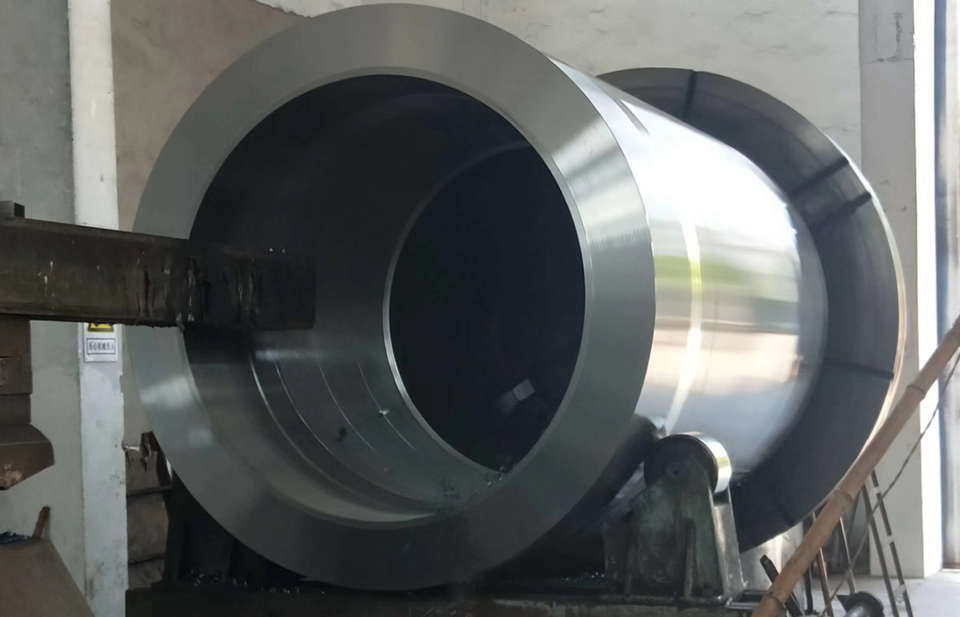

Wuxi Marley Metal Technology Co., Ltd. is a company engaged in the research and development, smelting, sales, and service of special metal alloy materials. The products are produced using high-power electric arc furnaces, AOD furnaces, LF furnaces, VD furnaces, continuous casting machines, 12-ton Consarc vacuum induction furnaces from the U.S., 15-ton Consarc atmosphere-protected electroslag furnaces, 12-ton ALD vacuum consumable furnaces from Germany, imported quick-forging machines, high-speed bar rolling mills, and wide medium-thick plate rolling mills. The company offers products such as steel ingots, electroslag ingots, consumable ingots, continuous casting billets, bars, special steel medium-thick plates, and high-temperature alloy cold-rolled sheets (customizable).

Why Choose Us

The service areas cover more than 30 industries, including automobiles, home appliances, elevators, engineering machinery, mining and cement equipment, petrochemicals, energy equipment, etc

Product Display

Supported by strong special steel supply channels

Enterprise Advantages

Supported by strong special steel supply channels

Years of experience in forging and forging processing

Our core team has nearly 20 years of industry experience. In addition to the domestic market, our products are exported to Europe, Southeast Asia, and beyond. We offer processing services including sawing, turning, milling, and heat treatment (annealing, normalizing, quenching, and tempering).

Strict quality control system

Our products undergo strict quality control at every stage, from cutting to delivery, ensuring flawless quality and customer peace of mind. We implement SS-level management with international production standards, reliable quality, and fast delivery.

Complete materials and complete business support

Main stock materials: 45#, 35#, 20#, 16Mn, Q345B, C, D, E, 40Cr, 20/35/42CrMo, 20/40CrNiMo, 34CrNiMo6, 34CrNi3Mo, 28MnMoNb, 20Cr2Ni4, 18Cr2Ni4W, 37SiMn2MoV, 60CrMoV and other forgings Processing materials.

The choice for high-standard customer needs

We provide full after-sales and technical support with guaranteed quality. Our carbon steel, tool steel, stainless steel, and more are widely used in industries like machine tools, welding, shipbuilding, and mining equipment.

Three Major Quality Control Tests

Ensure that every product leaves the factory qualified and eliminate hidden quality risks

Chemical Composition Testing

Verifies the elements in stainless steel to ensure it meets required specifications for performance and corrosion resistance.

Mechanical Performance Testing

Assesses the strength, toughness, and durability of stainless steel under various conditions.

Ultrasonic Flaw Detection

Uses sound waves to detect internal defects or inconsistencies in stainless steel without damaging the material.

Order Process

Follow the process and be responsible for every customer

Telephone Communication

Confirm Request

Detailed Quotation

Sign A Contract

Advance Payment

Workshop Order

Product Shipment

Balance Payment In Advance

Product Delivery

News

Strong special steel supply channel support

Partners

Our cooperative steel mills