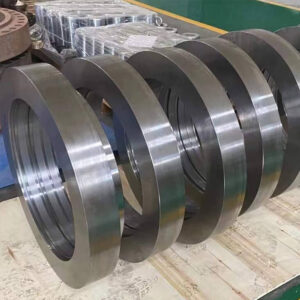

Ring Forgings are circular metal components created through forging processes to ensure superior strength and structural integrity. These products are widely used in heavy industries such as automotive, aerospace, construction, and energy sectors.

Ring Forgings – Product Details

| Category | Model/Specification | Features/Applications |

| By Material | Carbon Steel, Alloy Steel, Stainless Steel, Aluminum Alloy | Carbon for durability, alloy for high strength, stainless for corrosion resistance, aluminum for lightweight applications |

| By Process | Open Die Forging, Closed Die Forging, Ring Rolling | Open die for large, custom pieces; closed die for precise shapes; ring rolling for seamless rings |

| By Size | Outer Diameter: 200mm – 4000mm, Height: 50mm – 1000mm | Wide range of sizes to meet various industrial requirements |

| By Application | Gear Rings, Bearing Rings, Flanges, Slewing Rings | Used in heavy machinery, automotive, wind turbines, and aerospace |

| Standards | ASTM, EN, DIN, JIS | Compliant with international quality standards |

| Processing Capacity | Up to 2000 tons/month | High production capacity to meet large order demands |

| Surface Treatment | Machined, Polished, Heat Treated, Galvanized | Various treatments for improved performance and longevity |

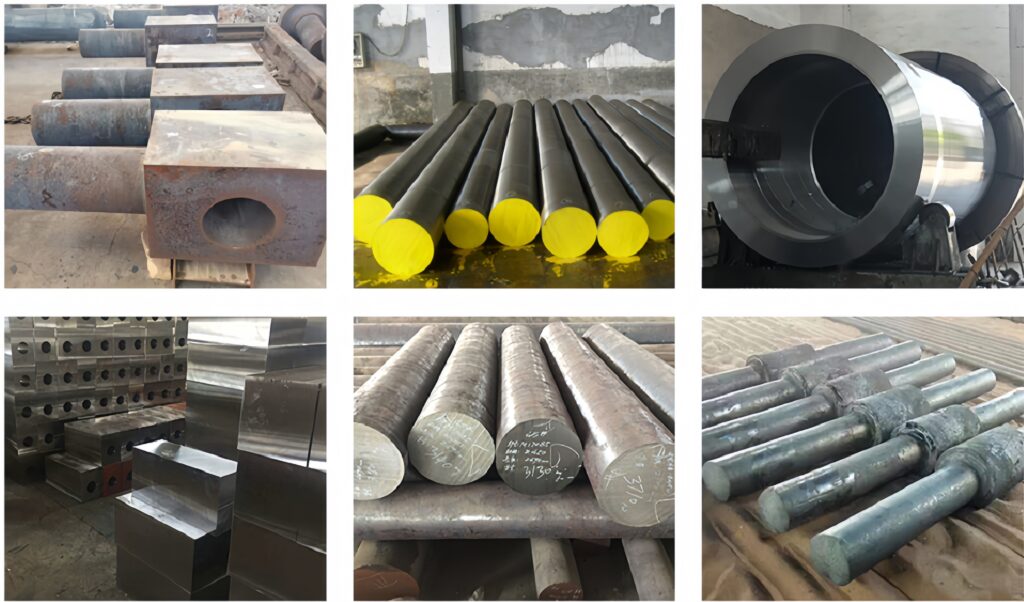

Product Display

Shafts are available in diameters ranging from 10mm to 200mm, with customizable lengths to fit specific project needs. Common applications include transmission shafts, drive shafts, axle shafts, and spindle shafts, used in automotive, industrial, and machinery systems.

Products are widely used in

Hoisting machinery, trains, petroleum, chemical industry, mining, metallurgy, electric power, offshore engineering ships, pressure vessels, molds and other industries

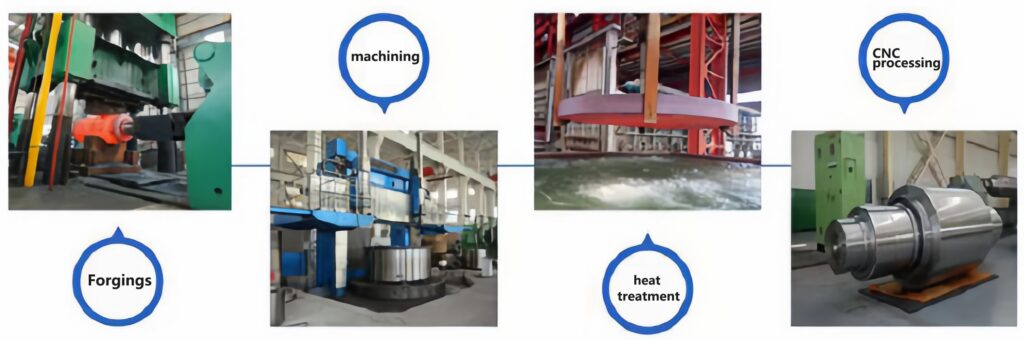

Processing capacity

The manufacturing process includes cold drawn shafts for precise dimensions, hot rolled shafts for strength, and precision ground shafts with smooth finishes for enhanced performance.

Reviews

There are no reviews yet.